Beitrag

von fotoopa » 23 Okt 2019, 11:17

Thanks, guys!

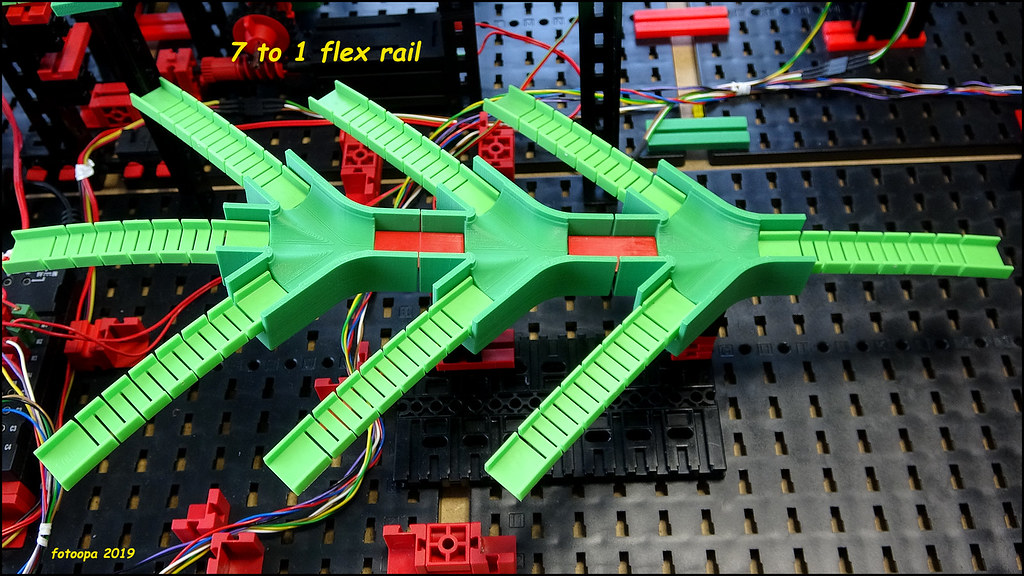

I'm currently making more blocks for my new extra large marble run. For this I have a volume of 1.2m x1.2m x0.8m. The used parts are the 5 kits XL, the XXL, the dynamic_XM and multiple boxes 1000.

The program will be developed for the TXT-Controller via Robopro. Almost everything goes via an I2C link to my FPGA chip as a large I2C chip. It can control 16 motors with rotary encoders, 4 steppers, 32 servo and a lot of in-outputs.

Because in an FPGA everything runs in parallel, there are no timing problems and most functions are executed completely autonomously. The 16 encoder decoders can handle over 20KHz speed, conventional inputs and outputs 40 KHz and high-speed inputs up to 10 MHz.

It should work by Christmas when the grandchildren arrive.

Frans.