The Rob hat geschrieben:Es gibt das Dynamic Tuningset und dieses Jahr kommen noch jede Menge anderer Erweiterungskästen raus. Die sind dafür prädestiniert

I use 4 of these 533873 dynamic tunning set sets, they are a very good addition for a low price.

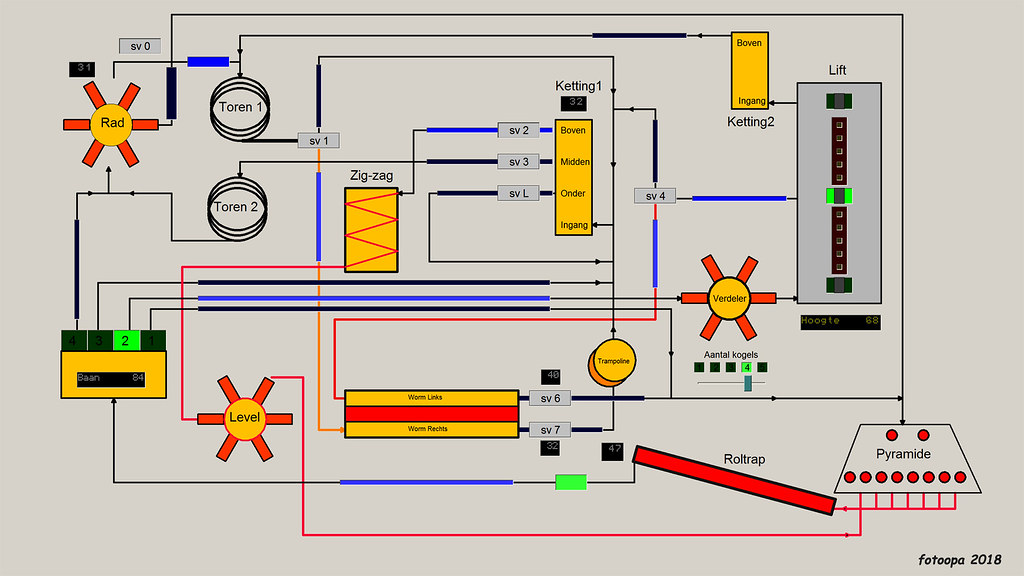

A small update of my super "kugelbahn".

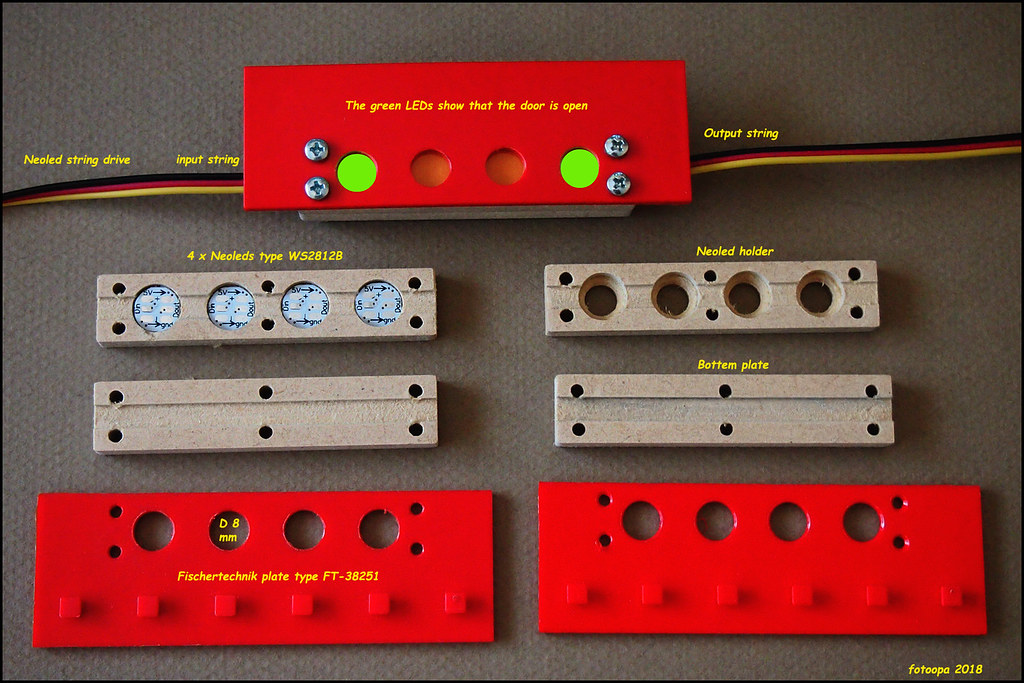

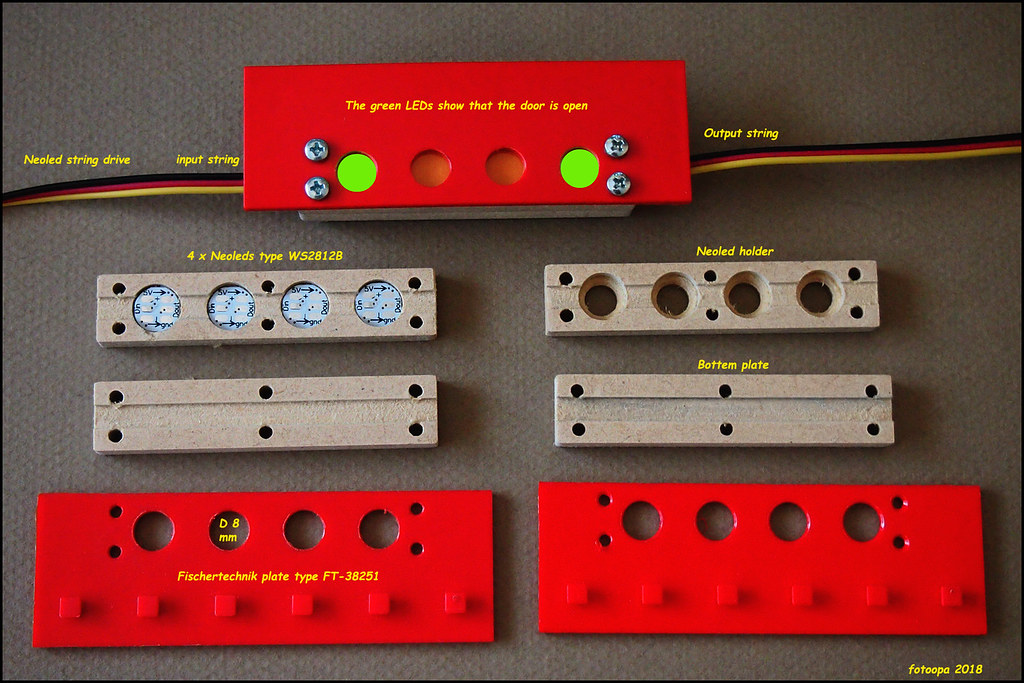

Neo LED construction with MDF wood board and Fischertechnik plate FT-38251.

Link to the Original picture:

https://www.flickr.com/photos/fotoopa_hs/39329122335

The Neoleds are placed in a block so that they can be connected to each other with a bare solder wire. You do not need a PCB. The 3-pin connector is clamped between the 2 wooden pieces and attached to the Fischertechnik plate FT-38251. Here 4 LEDs are placed in a row. The 2 outer LEDs indicate in green that the lift door is open. When the door is closed, the 2 central LEDs are shown in red. All Neoleds are in a string and each LED can have its own colour (24bit RGB). For the string control you only need 5V and only 1 drive pin of the controller. All LEDs fit in a string, I have 120 pieces available.

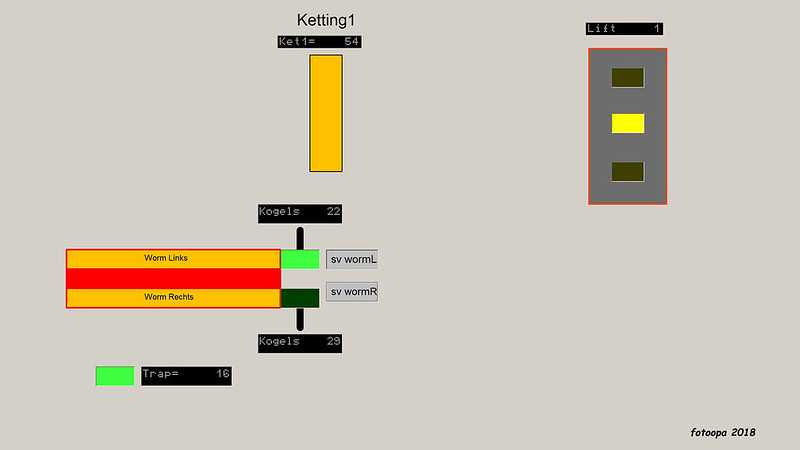

My lift of the trajectory has 3 double moving doors, which shows the status. Between the LEDs and Fischer Plate there is a white sheet of paper for light distribution + an orange colour filter to reduce the blue light somewhat.

As soon as the 3 LED indicators are mounted, I can start to make a video. Then everything will be even clearer. The various routes that are possible will also be shown regularly in a video. But this requires some video editing work!

Answers may also be the German language, I do read it.

Frans.