Designing a backlash-free drive with a worm screw.

Verfasst: 30 Dez 2018, 19:16

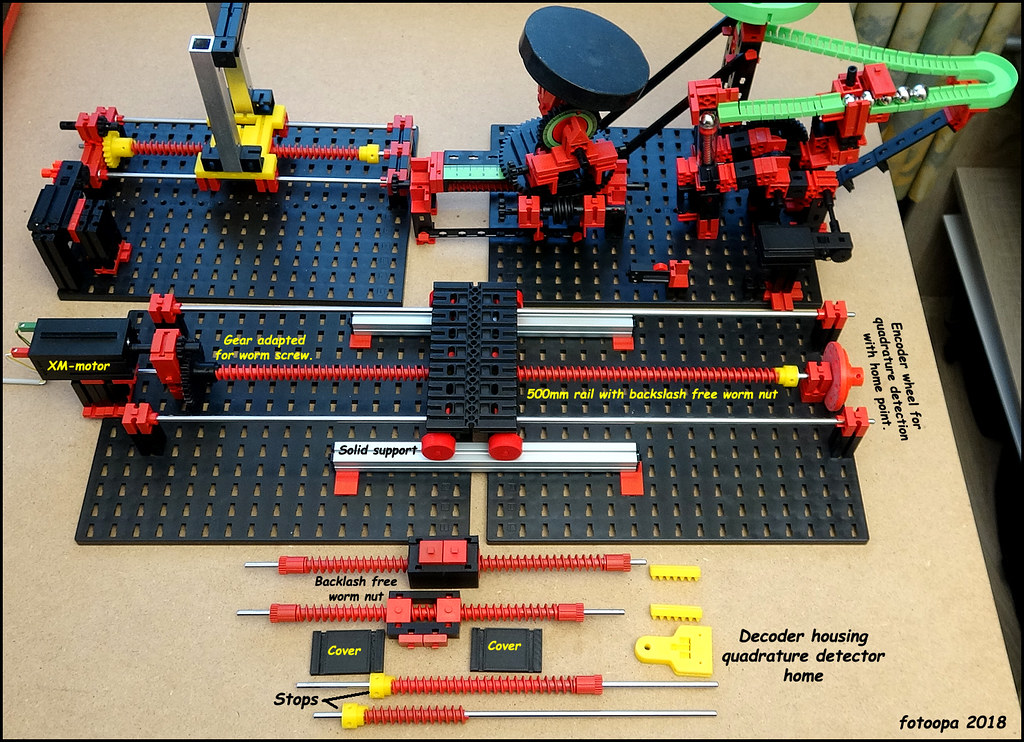

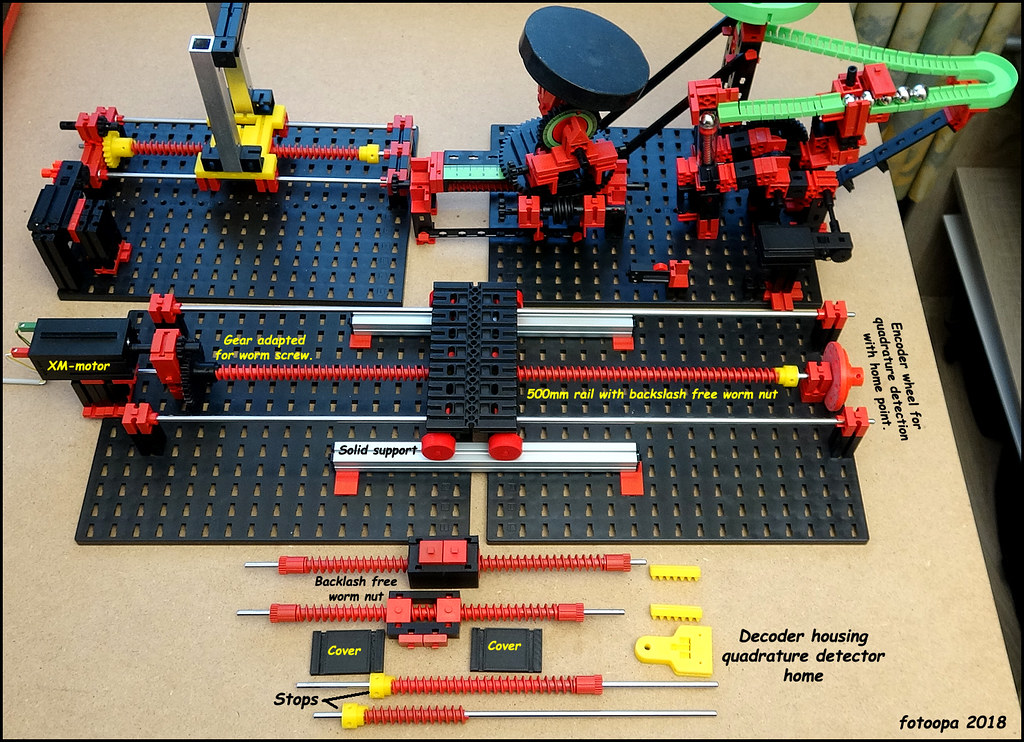

Designing a backlash-free drive with a worm screw. To eliminate the backlash, 2 worm screws are required that have a small shift. With only 1 worm screw you have about 0.6mm of backlash which is a lot.

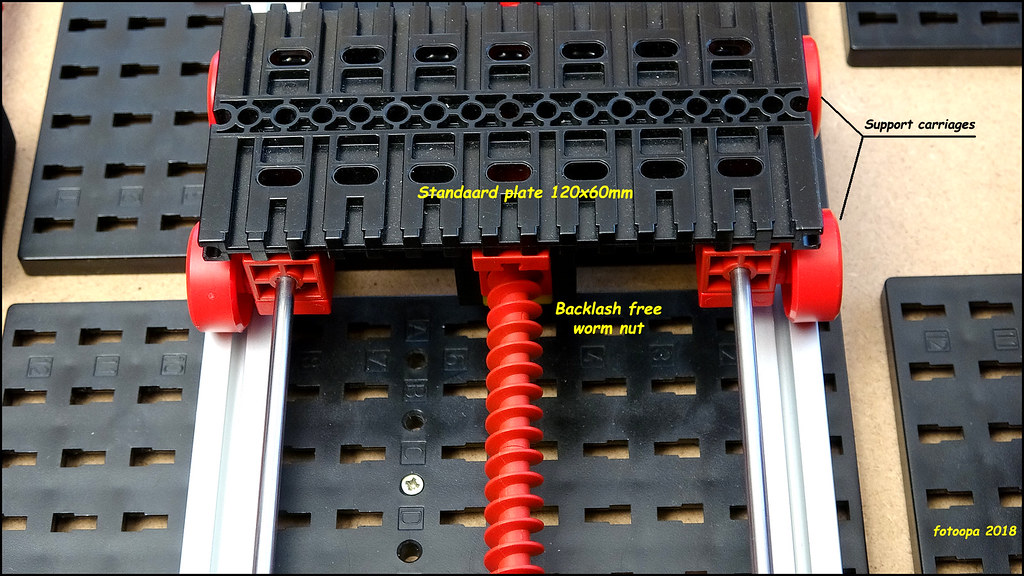

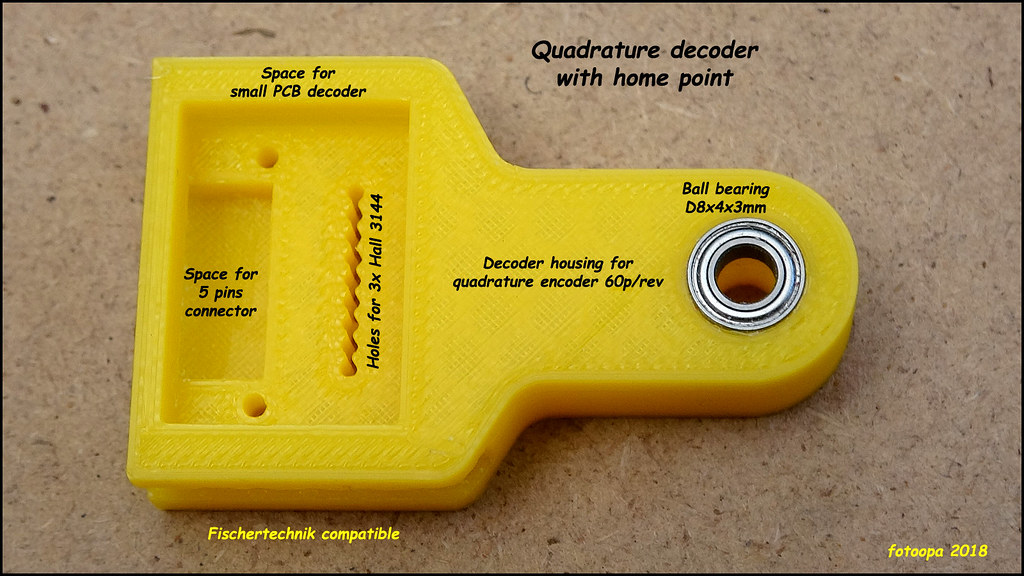

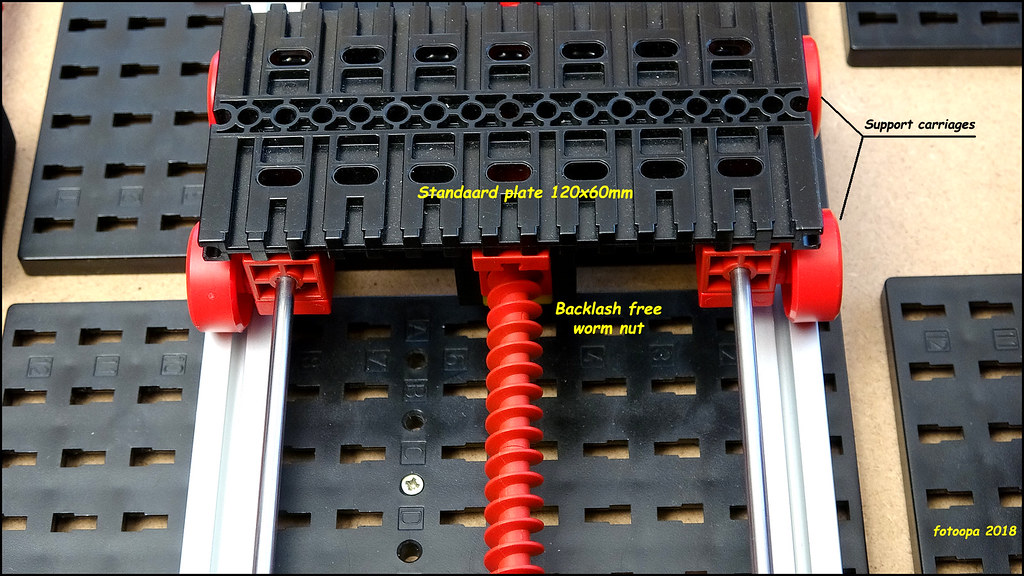

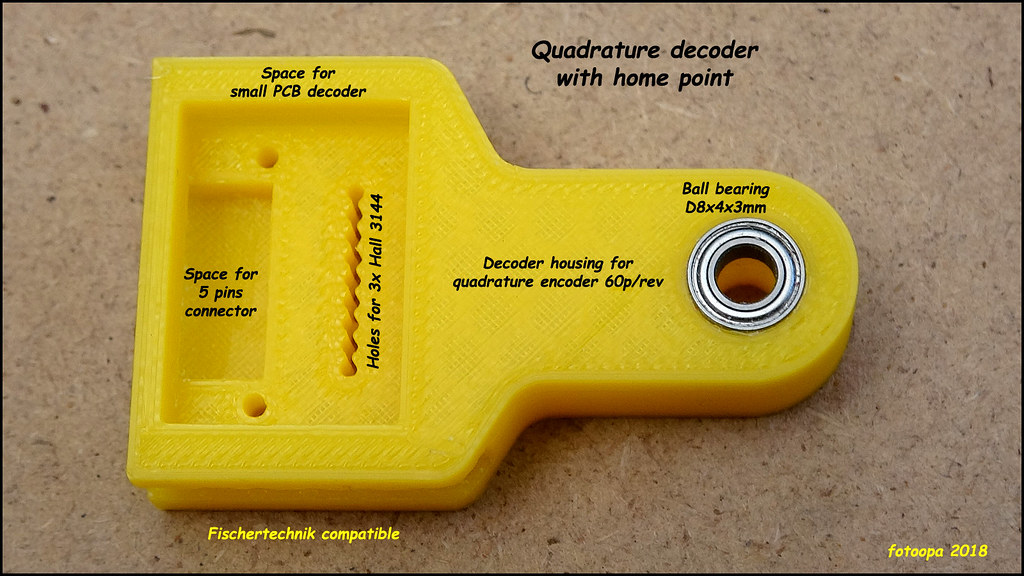

A custom housing now contains 2 worm screws at the right distance. These can easily be mounted on the standard base plate 120x60mm. In the setup I use shafts of 500mm length. To increase stability another 4 small support wheels are added that run on a flat surface. This way the carriage can not tilt and remains very stable. With an XM-motor and a gear reduction of 3 times the drive goes quite smoothly. At the end I made a worm screw stop (yellow plug). Also the gear of 30T contains an adjustment for the worm screw. In the foreground of the picture you see the details of the housing. I also made a quadrature decoder with home point with a ball bearing D8x4x3mm With an encoder disc with 15 neodymium magnets you get 60 pulses per tour or 0.0785 mm per pulse.

All files on Thingiverse: https://www.thingiverse.com/thing:3323197

A few pictures:

HD: https://www.flickr.com/photos/fotoopa_hs/31587974067

HD: https://www.flickr.com/photos/fotoopa_hs/31587973697

HD: https://www.flickr.com/photos/fotoopa_hs/31587973327

HD: https://www.flickr.com/photos/fotoopa_hs/32654940448

HD: https://www.flickr.com/photos/fotoopa_hs/32654940218

Frans.

A custom housing now contains 2 worm screws at the right distance. These can easily be mounted on the standard base plate 120x60mm. In the setup I use shafts of 500mm length. To increase stability another 4 small support wheels are added that run on a flat surface. This way the carriage can not tilt and remains very stable. With an XM-motor and a gear reduction of 3 times the drive goes quite smoothly. At the end I made a worm screw stop (yellow plug). Also the gear of 30T contains an adjustment for the worm screw. In the foreground of the picture you see the details of the housing. I also made a quadrature decoder with home point with a ball bearing D8x4x3mm With an encoder disc with 15 neodymium magnets you get 60 pulses per tour or 0.0785 mm per pulse.

All files on Thingiverse: https://www.thingiverse.com/thing:3323197

A few pictures:

HD: https://www.flickr.com/photos/fotoopa_hs/31587974067

HD: https://www.flickr.com/photos/fotoopa_hs/31587973697

HD: https://www.flickr.com/photos/fotoopa_hs/31587973327

HD: https://www.flickr.com/photos/fotoopa_hs/32654940448

HD: https://www.flickr.com/photos/fotoopa_hs/32654940218

Frans.